濟南聚大邦成化工有限公司

聯系人:張總

電話:13583111587

網址:placebuddy.net

地址:濟南市天橋區新材料市場南區7-1-1

精萘生成方法離不開哪些原料?

1.由石油烴制得:催化重質重整油,催化裂化輕循環油,裂解制乙烯的副產焦油等;

1. Produced from petroleum hydrocarbons: catalytic heavy reforming oil, catalytic cracking light cycle oil, by-product tar from cracking to ethylene, etc;

2.由煤焦油分離,高溫煤焦油中萘約占8%-12%,將煤焦油蒸餾,切取煤油,經脫酚,脫喹啉,蒸餾得成品萘。每噸萘消耗10t煤焦油;

2. By separating coal tar, naphthalene accounts for about 8% -12% in high-temperature coal tar. Distill the coal tar, cut the kerosene, remove phenols, remove quinolines, and distill to obtain finished naphthalene. Each ton of naphthalene consumes 10 tons of coal tar;

3.粗萘經白土精制而得精萘;

3. Refined naphthalene is obtained by refining crude naphthalene with clay;

4.降膜分步結晶法 結晶法生產過程由產品生產工藝系統、能源系統、氮氣密封系統和計算機控制系統等組成。生產工藝系統以大循環為生產周期,每個大循環包含4個小循環,每個小循環又包含4~6個段,每個段由結晶、部分熔融和全部熔融3個步驟組成;

The production process of the falling film step-by-step crystallization method consists of a product production process system, an energy system, a nitrogen sealing system, and a computer control system. The production process system takes a large cycle as the production cycle, with each large cycle containing 4 small cycles and each small cycle containing 4-6 segments. Each segment consists of three steps: crystallization, partial melting, and complete melting;

(降膜結晶法操作工藝實例:由工業萘裝置送來的液態工業萘送入餾分槽中,當進行第四段結晶操作時,用泵將槽中的原料液送入動態結晶器收集槽中。未結晶萘油與發汗液放入純度低一級的餾分槽中,全熔液可作為第五段的原料。按預定程序進行六段結晶精制后即可得到產品精萘。為提高萘的提取率,可將富含硫茚的餾分送往靜態結晶器中處理,靜態結晶器所得的產品返回動態結晶系統的相應餾分槽,殘液可作為減水劑出售。由于該裝置同時采用動態和靜態結晶器,既可保證較高的萘回收率,又能降低能耗。)

Example of falling film crystallization operation process: Liquid industrial naphthalene sent from the industrial naphthalene unit is sent to the distillation tank. When the fourth stage crystallization operation is carried out, the raw material liquid in the tank is pumped into the dynamic crystallizer collection tank. Uncrystallized naphthalene oil and sweating liquid are placed in the lower purity distillation tank, and the full melt can be used as the raw material for the fifth stage. After six stages of crystallization refining according to the predetermined procedure, the product refined naphthalene can be obtained. To improve the extraction rate of naphthalene The fraction rich in sulfur indene can be sent to a static crystallizer for processing, and the product obtained from the static crystallizer can be returned to the corresponding distillation tank of the dynamic crystallization system. The residual liquid can be sold as a water reducing agent. Due to the use of both dynamic and static crystallizers in this device, it can ensure a high naphthalene recovery rate while reducing energy consumption

5.靜態分步結晶法 將原料工業萘裝入結晶箱后進行快速降溫,降至82℃后轉為均勻降溫,以2℃/h的降溫速度冷卻至60℃,排放富含硫茚的第一次晶析萘油,作為中間餾分待后處理。然后結晶箱內的物料以4℃/h的速度升溫,間隔0.5h取樣一次,測定其結晶點,根據結晶點的不同,分別排入對應餾分槽,如此進行3~4次分步結晶,可得到較高純度的精萘。

5. Static stepwise crystallization method: The raw material industrial naphthalene is loaded into a crystallization box for rapid cooling, and after cooling to 82 ℃, it becomes uniformly cooled. It is cooled at a cooling rate of 2 ℃/h to 60 ℃, and the first crystallization naphthalene oil rich in sulfur indene is discharged as an intermediate fraction for post-treatment. Then, the material inside the crystallization box is heated at a rate of 4 ℃/h, and samples are taken every 0.5 hours to determine its crystallization point. According to the different crystallization points, they are discharged into the corresponding distillation tanks. This process is carried out 3-4 times in steps to obtain high-purity refined naphthalene.

更多的關于精萘廠家問題或者詳細的內容,請進入我們公司的網站:http://placebuddy.net網站中會有很多的內容僅供參考

For more questions or detailed information about refined naphthalene manufacturers, please visit our company's website: http://placebuddy.net There will be a lot of content on the website for reference only

推薦閱讀/ Recommended reading

- 精萘能做成什么? 2025-05-03

- 精萘有什么用呢? 2025-04-12

- 精萘的危害和預防措施 2025-04-02

- 是什么促成精萘廠家成為化工領域的關鍵力量呢? 2025-03-17

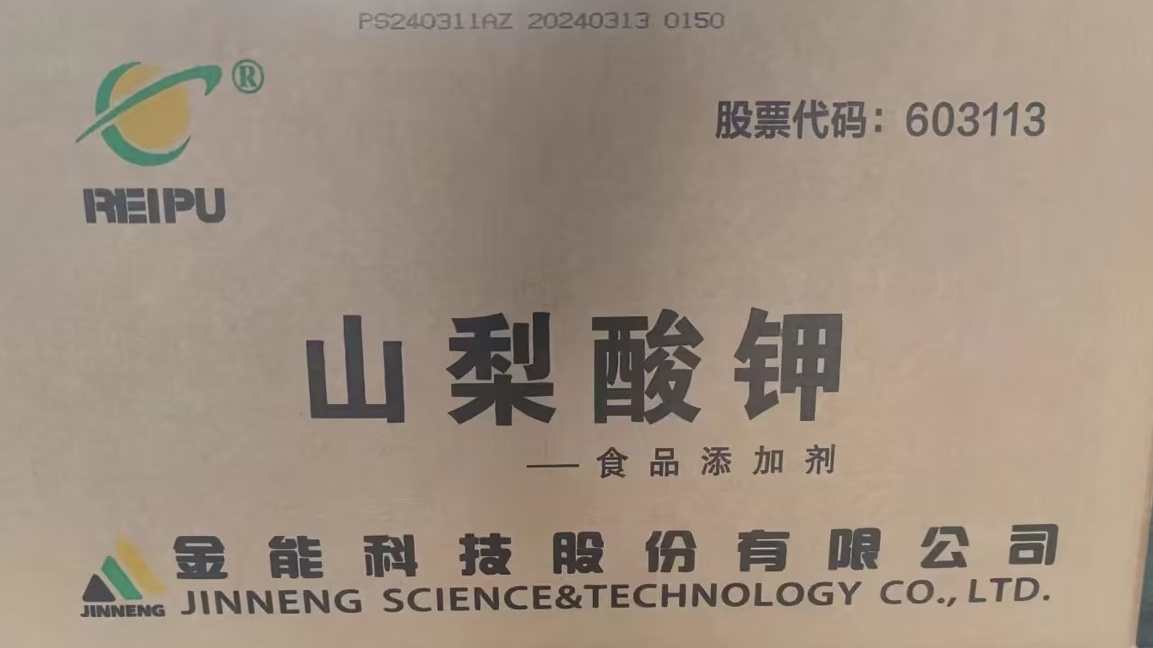

一、認識山梨酸鉀?1、 Get to know potassium sorbate山梨酸鉀,又名 2,4 - 己二烯酸鉀,是山梨酸的鉀鹽,分子式為 C?H?O?K 。從外觀上看,...