濟南聚大邦成化工有限公司

聯(lián)系人:張總

電話:13583111587

網(wǎng)址:placebuddy.net

地址:濟南市天橋區(qū)新材料市場南區(qū)7-1-1

精萘廠家:精萘的生產(chǎn)方式辨別

萘又稱井萘是一種無色有光澤的片狀結晶。不溶于水,易升華,能隨水蒸氣揮發(fā),有特殊氣味。是工業(yè)上最重要的稠環(huán)芳經(jīng)可用于生產(chǎn)苯酐、染料的中間體、橡膠助劑和殺蟲劑。

Naphthalene, also known as well naphthalene, is a colorless and glossy crystalline flake. Insoluble in water, prone to sublimation, can evaporate with water vapor, and has a special odor. It is the most important polycyclic aromatic hydrocarbon in industry that can be used as an intermediate in the production of phthalic anhydride, dyes, rubber additives, and insecticides.

根據(jù)純度不同,萘可分為工業(yè)蔡和精萘。工業(yè)蔡的純度一般約為96%。工業(yè)蔡進一步提純脫除雜質及脫硫后,可得到高純度的精萘。

According to different purities, naphthalene can be divided into industrial naphthalene and refined naphthalene. The purity of industrial Cai is generally about 96%. After further purification and removal of impurities and desulfurization, industrial Cai can obtain high-purity refined naphthalene.

生產(chǎn)和制備簡介:

Introduction to Production and Preparation:

1.從石油烴類制造:催化重整油,輕循環(huán)油催化裂化,乙烯裂解副產(chǎn)物焦油等;

1. Manufacturing from petroleum hydrocarbons: catalytic reforming oil, light cycle oil catalytic cracking, ethylene cracking by-product tar, etc;

2.與煤焦油分離,高溫煤焦油中的萘約占8%-12%。將煤焦油蒸餾,將煤油切碎,并通過脫酚和脫喹啉蒸餾獲得最終的萘。

2. Separation from coal tar, naphthalene in high-temperature coal tar accounts for about 8% -12%. Distill the coal tar, cut the kerosene into small pieces, and obtain the final naphthalene through dephenolization and quinoline removal distillation.

3.精萘是將粗萘精制而成。

3. Refined naphthalene is refined from crude naphthalene.

4.降膜分步結晶結晶生產(chǎn)工藝流程由產(chǎn)品生產(chǎn)工藝系統(tǒng),能量系統(tǒng),氮氣密封系統(tǒng)和計算機控制系統(tǒng)組成。生產(chǎn)過程系統(tǒng)將大周期用作生產(chǎn)周期。每個大周期包含4個小周期,每個小周期包含4至6個段。每個段包括3個步驟:結晶,部分熔融和全部熔融;

The production process of falling film fractional crystallization crystallization consists of a product production process system, an energy system, a nitrogen sealing system, and a computer control system. The production process system uses large cycles as production cycles. Each large cycle contains 4 small cycles, and each small cycle contains 4 to 6 segments. Each section includes three steps: crystallization, partial melting, and complete melting;

(從工業(yè)萘裝置送來的液態(tài)工業(yè)萘被送到餾出罐,當進行第四階段結晶操作時,罐中的原料液體被送到動態(tài)結晶器收集槽

The liquid industrial naphthalene sent from the industrial naphthalene unit is sent to the distillation tank. When the fourth stage crystallization operation is carried out, the raw material liquid in the tank is sent to the dynamic crystallizer collection tank

未結晶的萘油和汗液放入純度較低的分餾罐中,并且在第五階段中可以將全部熔體用作原料。可以根據(jù)預定程序在六個階段的晶體精制之后獲得精致的萘。為了提高萘的萃取率,可以將富含硫茚的餾分送入靜態(tài)結晶器進行處理。從靜態(tài)結晶器中獲得的產(chǎn)品返回到動態(tài)結晶系統(tǒng)的相應分餾罐中,殘留液體可以作為減水劑出售。由于該設備同時使用動態(tài)和靜態(tài)結晶器,因此不僅可以確保更高的萘回收率,而且可以減少能耗。 )

Uncrystallized naphthalene oil and sweat are placed in a lower purity fractionation tank, and in the fifth stage, all the melt can be used as raw materials. Refined naphthalene can be obtained after six stages of crystal refinement according to the predetermined program. In order to improve the extraction rate of naphthalene, the fraction rich in sulfur indene can be sent to a static crystallizer for processing. The product obtained from the static crystallizer is returned to the corresponding distillation tank of the dynamic crystallization system, and the residual liquid can be sold as a water reducing agent. Due to the use of both dynamic and static crystallizers, this device not only ensures higher naphthalene recovery rates but also reduces energy consumption

5.靜態(tài)逐步結晶將原料工業(yè)萘裝入結晶箱中,然后快速冷卻至82°C。之后,將其以2°C/h的冷卻速率均勻冷卻至60°C,即排放量豐富。硫代茚的萘油的第一次結晶用作中間餾分進行后處理。然后將結晶箱中的物料以4°C/h的速率加熱,并以0.5h的間隔取樣,并測量結晶點。根據(jù)不同的結晶點,它們被排入相應的分餾罐。這樣,可以進行3至4次結晶。獲得了更高純度的精制萘。

5. Static stepwise crystallization: The raw material industrial naphthalene is loaded into a crystallization box and then rapidly cooled to 82 ° C. Afterwards, cool it uniformly at a cooling rate of 2 ° C/h to 60 ° C, which results in abundant emissions. The first crystallization of naphthalene oil containing thioindene is used as an intermediate fraction for post-treatment. Then heat the material in the crystallization box at a rate of 4 ° C/h, take samples at intervals of 0.5 hours, and measure the crystallization point. According to different crystallization points, they are discharged into the corresponding distillation tanks. In this way, 3 to 4 crystallization cycles can be carried out. Obtained higher purity refined naphthalene.

推薦閱讀/ Recommended reading

- 精萘能做成什么? 2025-05-03

- 精萘有什么用呢? 2025-04-12

- 精萘的危害和預防措施 2025-04-02

- 是什么促成精萘廠家成為化工領域的關鍵力量呢? 2025-03-17

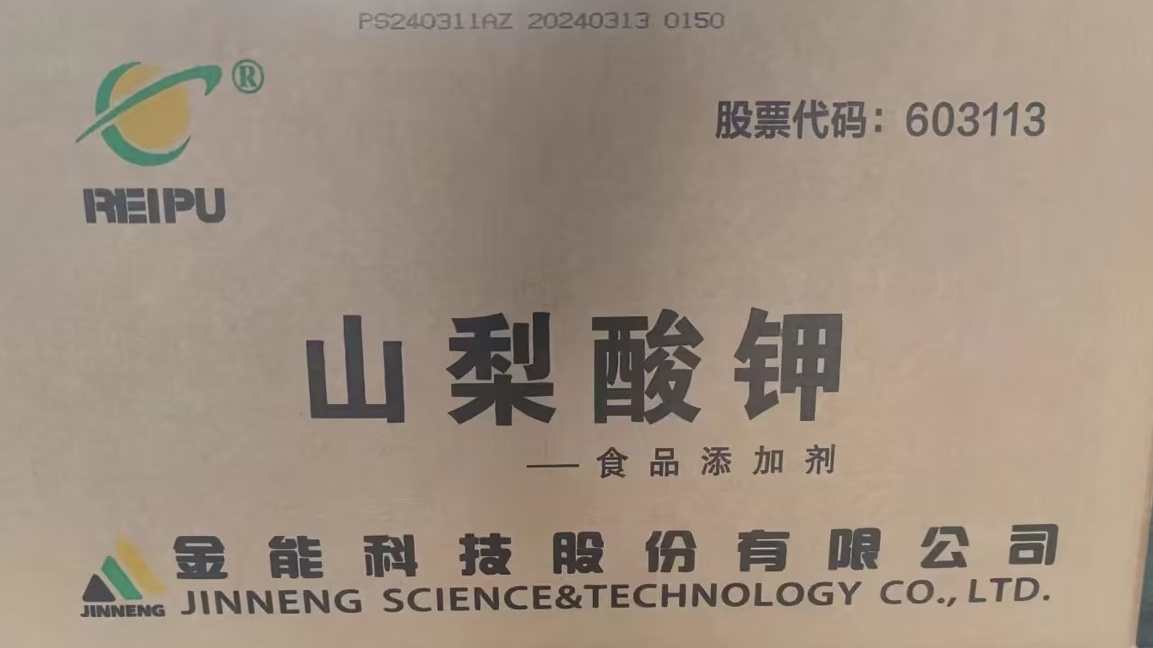

一、認識山梨酸鉀?1、 Get to know potassium sorbate山梨酸鉀,又名 2,4 - 己二烯酸鉀,是山梨酸的鉀鹽,分子式為 C?H?O?K 。從外觀上看,...